Welcome to Shenzhen Vowin Model Design CO., LTD Website!

A one-stop product development assistance platform from design to mold mass production, to become a first-class manufacturing enterprise

- E-mail: vowin@vip.163.com

- Hotline : +86-18665838950

Welcome to Shenzhen Vowin Model Design CO., LTD Website!

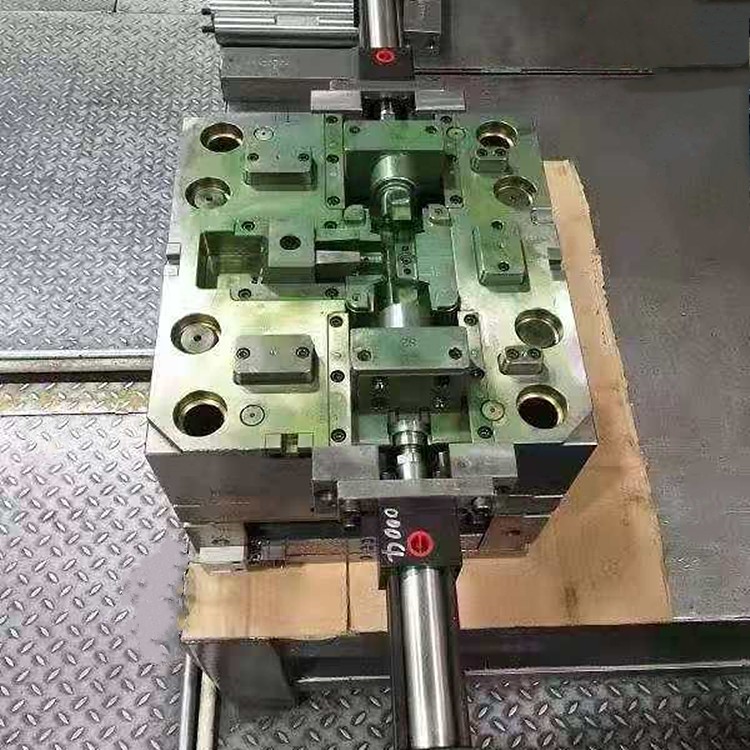

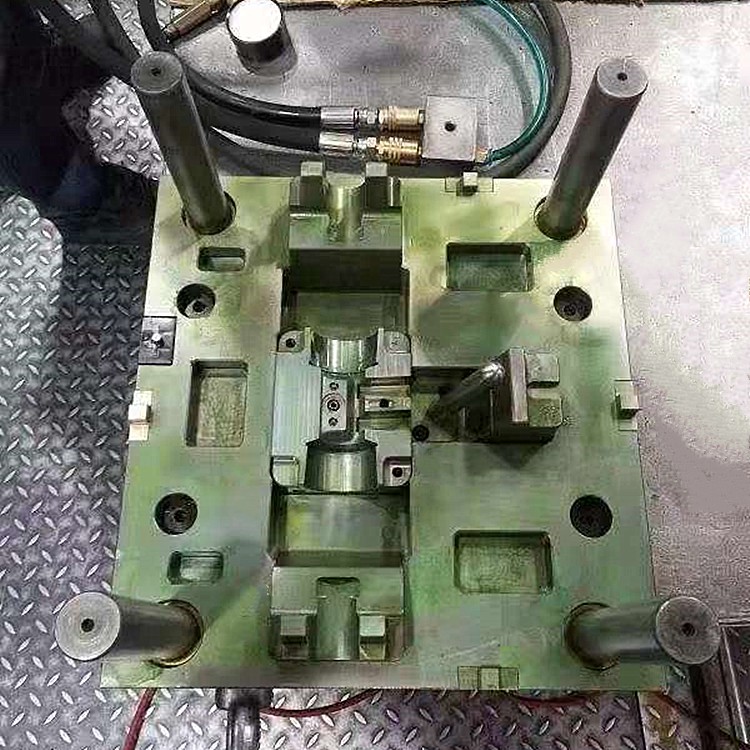

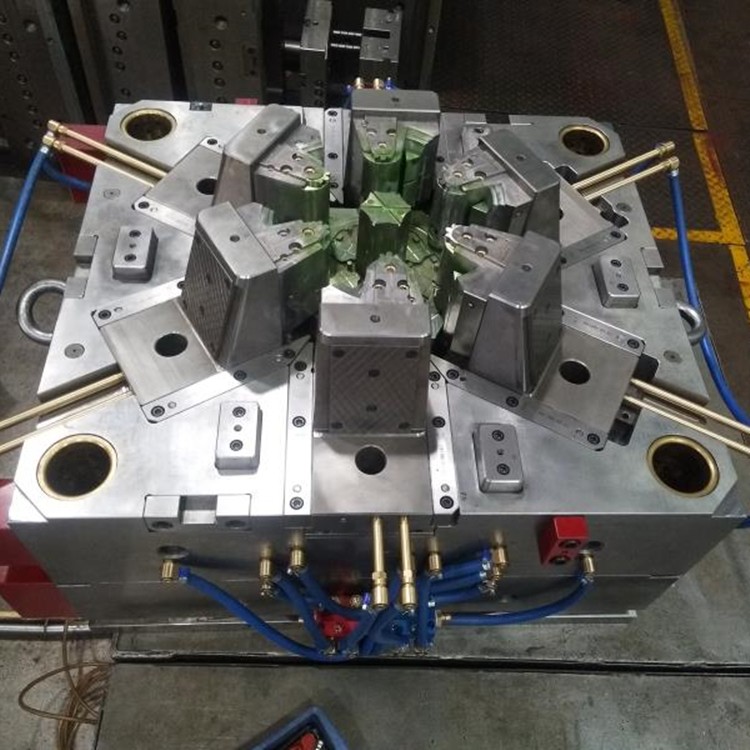

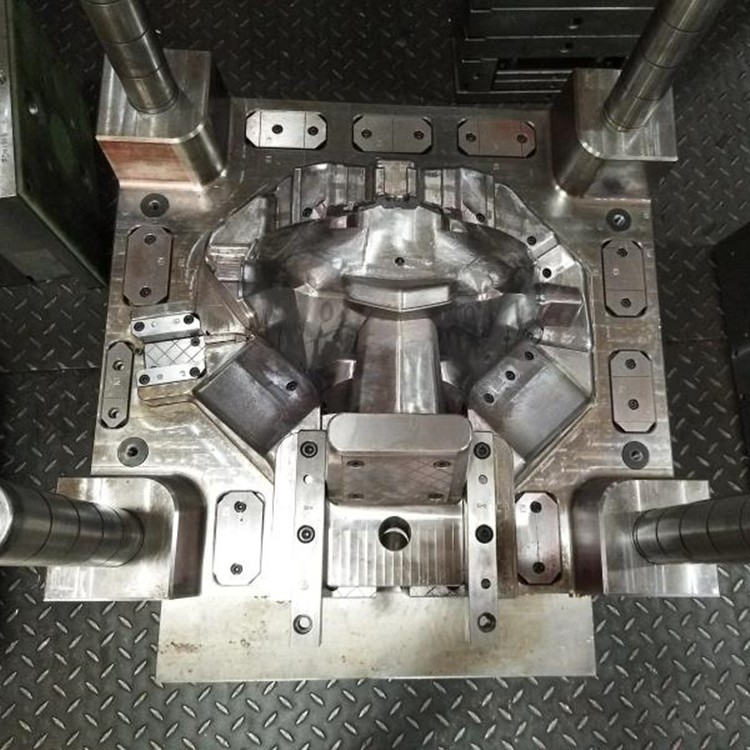

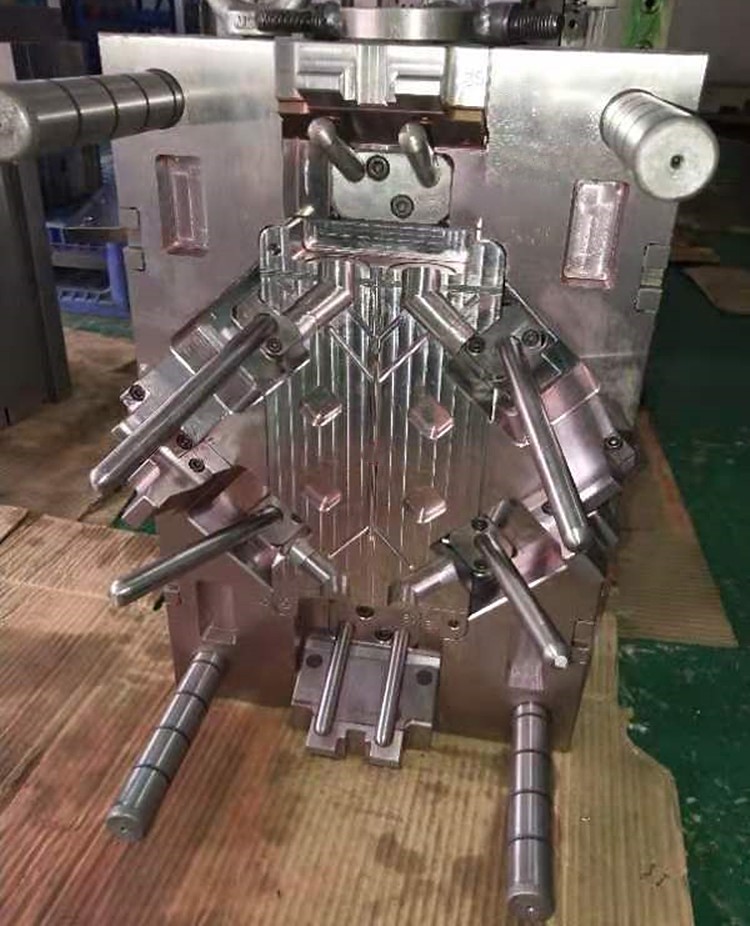

Mold making

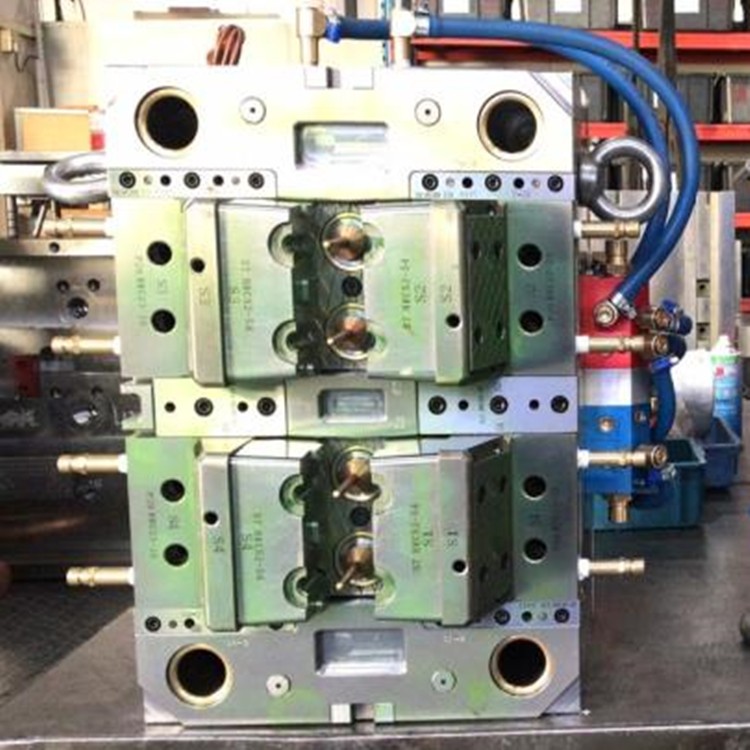

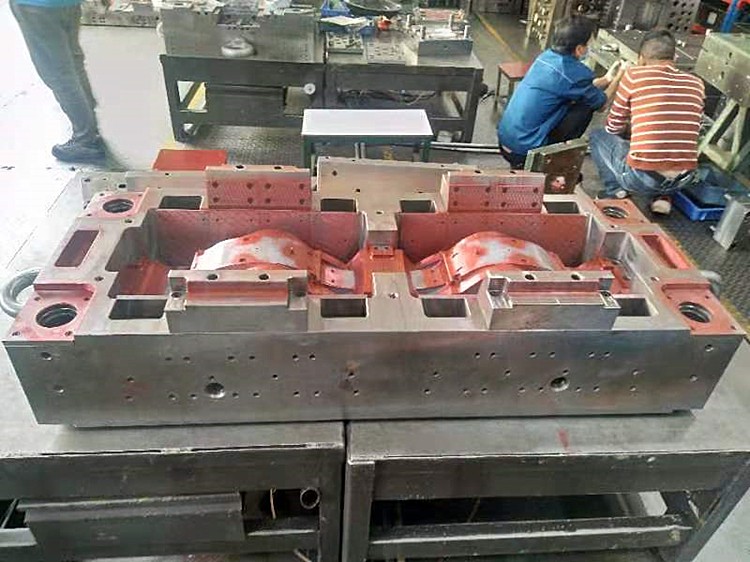

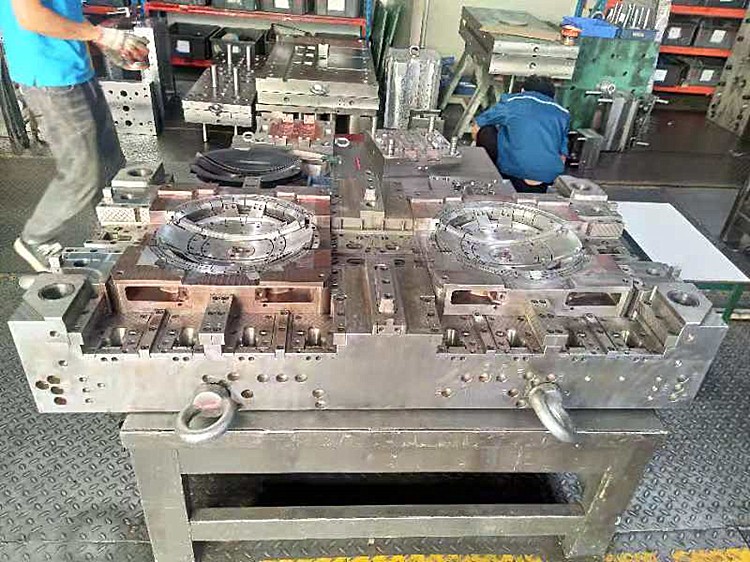

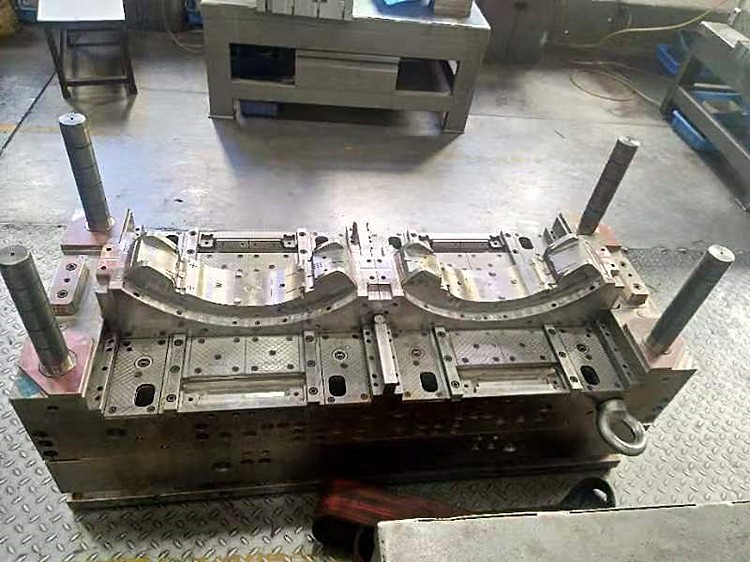

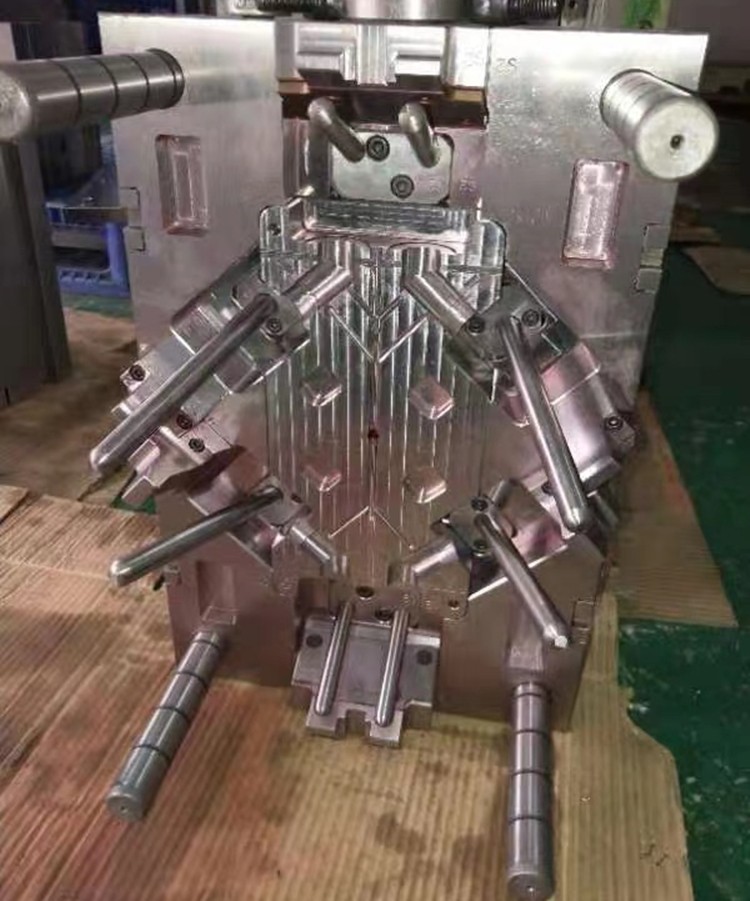

Mold making is divided into three categories: 1. Quick molds 2. Plastic molds 3. Product injection molding

1、 Quick mold:Quick mold refers to a special type of mold that simplifies the structure and materials of the mold, reduces mold costs, and reduces production cycles,

Advantages: Short production cycle, relatively low cost compared to standard plastic molds, but products with the same physical properties as standard molds can be obtained through injection molding. This has significant advantages for products with simple structure and low requirements for the number of components

Disadvantages: Short lifespan, relatively high cost per piece of beer, not suitable for mass production, and not suitable for products with complex structures,

Application scope: Medical, sports equipment, and some start-up enterprises

Service Cases

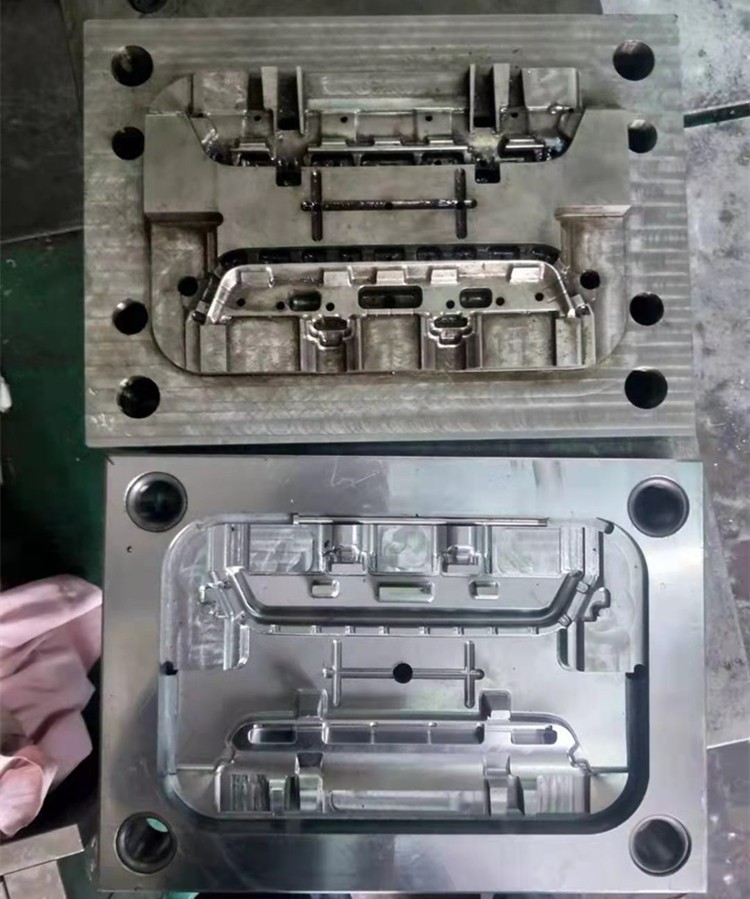

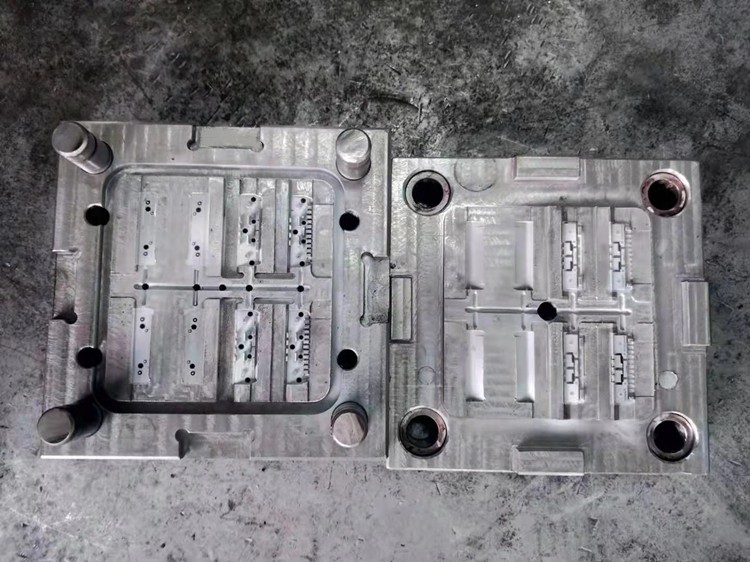

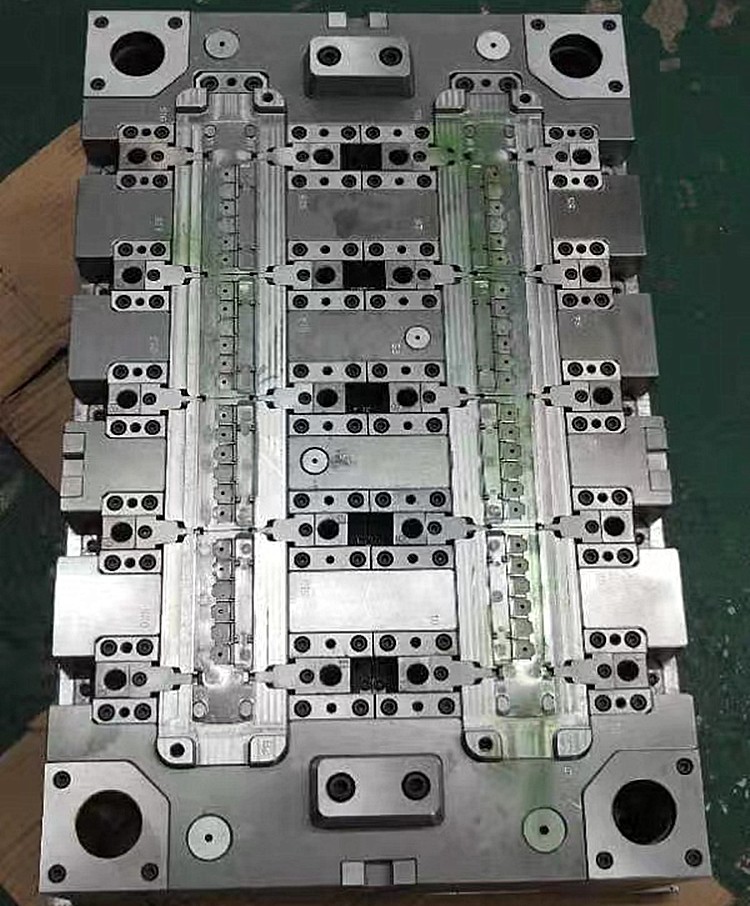

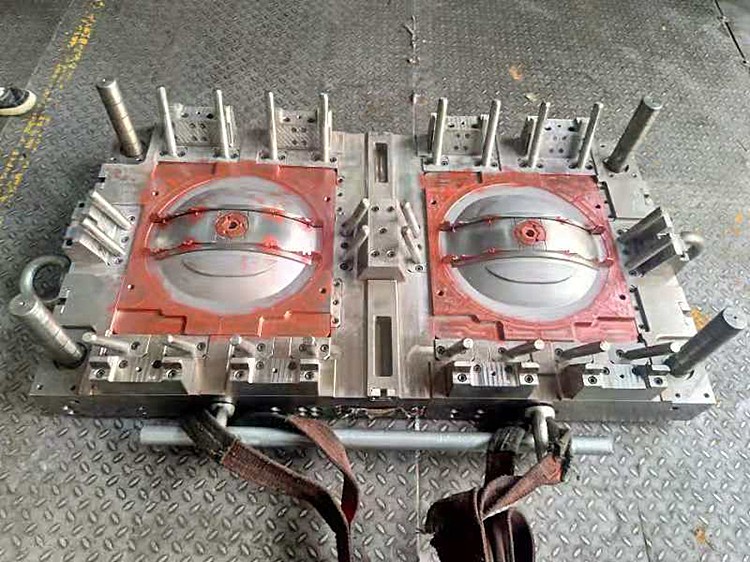

2、 Plastic mold

Plastic molds are the mother of industry. Some customers neglect communication with mold making units at the beginning of design and development, which can easily lead to the following problems:

1. Difficulty in mold opening: Some structural designs have achieved functional requirements and prototype testing has been conducted. However, when preparing for mold opening, local mold opening difficulties are discovered, and the structure needs to be redesigned, which prolongs the development cycle

2. Increasing the complexity of the mold: The complexity of the mold structure means an increase in mold costs. Reasonable structural design can simplify the mold structure, thereby reducing mold costs and increasing mold lifespan

3. Increase production costs: Injection materials with the same structural dimensions but different physical properties will be obtained. Familiarity with the physical properties of the materials can provide the best product parameters (wall thickness size, fitting position size) during design, avoiding unnecessary material waste

Service Cases

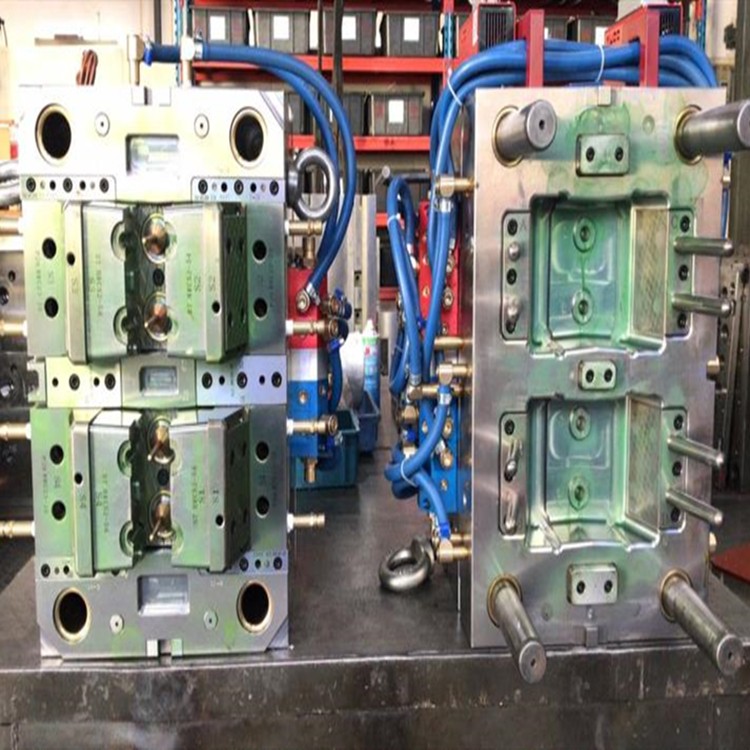

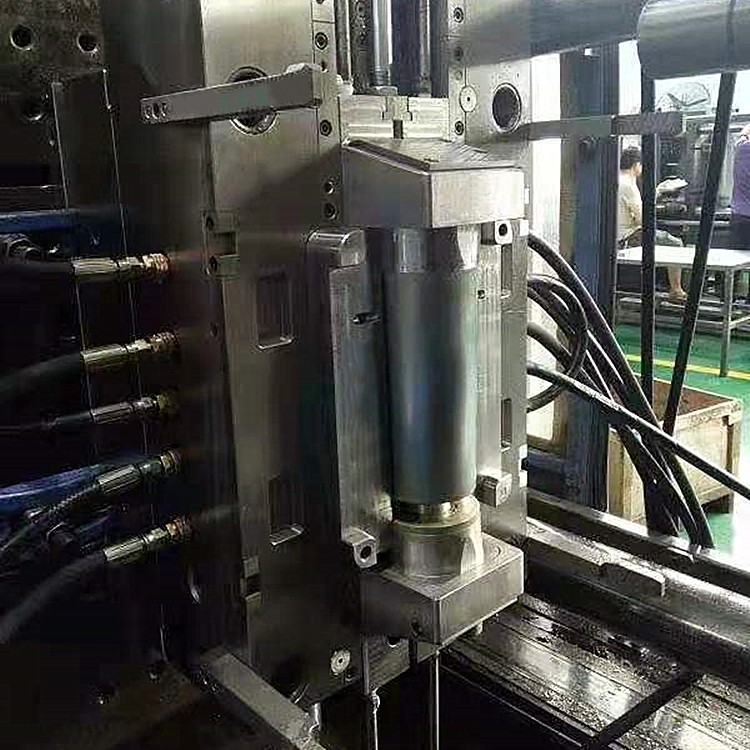

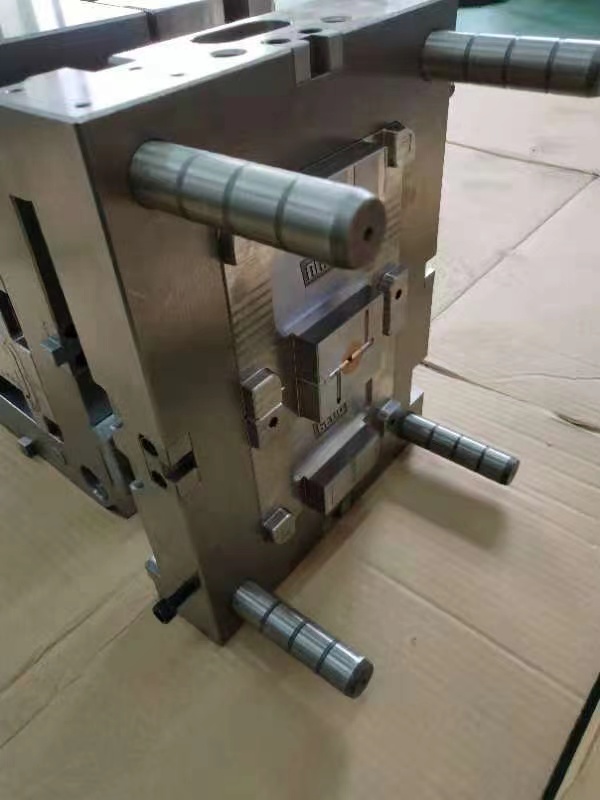

3、 Product injection molding

Common injection molding materials: ABS PP PE PC PA POM PBT PMMA

Copyright © 2023 Shenzhen Vowin Model Design Co., Ltd. All Rights ReservedGuangdong ICP No. 2023004751