Welcome to Shenzhen Vowin Model Design CO., LTD Website!

A one-stop product development assistance platform from design to mold mass production, to become a first-class manufacturing enterprise

- E-mail: vowin@vip.163.com

- Hotline : +86-18665838950

Welcome to Shenzhen Vowin Model Design CO., LTD Website!

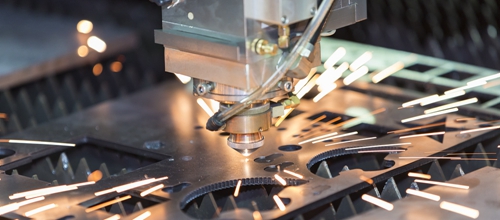

Sheet Metal Bending, the bending and forming of metal sheets are carried out on a bending machine. The workpiece to be formed is placed on the bending machine, and the brake shoe is lifted by a lifting lever. The workpiece slides to the appropriate position, and then the brake shoe is lowered onto the workpiece to be formed. The metal is bent and formed by applying force to the bending lever on the bending machine.

The minimum bending radius is a function of the ductility and thickness of the formed metal. For aluminum plates, the bending radius of the metal should be greater than the thickness of the plate. When bending, due to a certain degree of rebound, the angle of metal bending is slightly larger than the required angle. The bending of metal sheets is carried out in the metal processing workshop.

Common surface treatment methods for sheet metal processing include wire drawing, sandblasting, baking paint, powder coating, main technical indicators: glossiness, film thickness and color difference, electroplating (mainly plating multicolored zinc, white zinc, black zinc, chrome plating), polishing, and oxidation.

In the process of sheet metal processing, sometimes bending operations are required. What safety issues should be paid attention to during bending in sheet metal processing?

Before bending, it is necessary to inspect the relevant mechanical tools used for the lock. If any problems are found during inspection, processing operations must not be carried out, otherwise certain safety issues may occur.

What are the surface treatment methods for sheet metal processing parts?

The commonly used ones are: 1. Galvanizing; 2. Chrome plating; 3. Spray painting; 4. Electrostatic powder spraying.

Most of the sheet metal parts we usually see have patterns on the surface, which are obtained after surface treatment and can effectively protect the sheet metal parts from external factors such as rust and deformation. Surface treatment of sheet metal is an important procedure in sheet metal processing.

When bending sheet metal processing, remember that safety always comes first at all times.

Mainly explain some key points and focal points during the processing.

1. After adjusting the tailgate, it is strictly prohibited to adjust the tailgate fine-tuning nut to avoid affecting the accuracy of the machine tool

2. Before running the program, the molds should be staggered and the program should run empty once to ensure safety

3. During the operation of the machine tool, if there is an unexpected situation, do not panic and be sure to quickly press the emergency stop button

4. The on/off button for sheet metal processing cannot be pressed casually. Before each shutdown, remember to reset the MS axis to zero and wait for 10 seconds before starting up.

Copyright © 2023 Shenzhen Vowin Model Design Co., Ltd. All Rights ReservedGuangdong ICP No. 2023004751